Yiwen Wu

Engineer · Designer · Baker · Traveler

Breast Pump for Low-Resource Settings

January 2015 - April 2015

Four Team Members

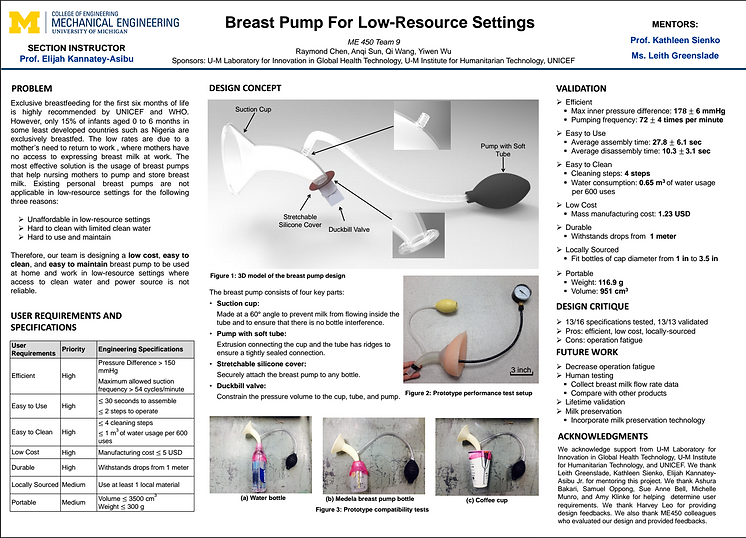

At least 800,000 children's lives could be saved each year if they were exclusively breastfed for the first 6 months. Currently, only 15% of infants aged 0 to 6 months in some least developed countries (e.g. Nigeria) are exclusively breastfed due in part to the need for mothers to return to work and limited resources. The goal of this project is to design a low cost, easy to use, and clean breast pump that is suitable for use at home and work in low-resource setting. This is a 4-month capstone design project sponsored by UNICEF, U-M Laboratory for Innovation in Global Health Technology, and U-M Institute for Humanitarian Technology.

Inspiration

Conducted desk research and literature reviews to understand current status of breastfeeding and challenges of breast pump usage in low-resource settings.

Interviewed project sponsors, faculty mentors, pediatricians and OB/GYN specialists from Ghana, Philips breast pump team, PATH maternal & child health/nutrition team, and other project stakeholders.

Conducted product benchmarking and evaluated existing breast pumps for various market segments.

"Breastfeeding is the most effective and least costly life-saver ever!"

-

Exclusive breastfeeding for the first 6 months of life is highly recommended by UNICEF and WHO based on its extraodinary range of benefits to both mothers and children.

-

Only 15% of infants aged 0 to 6 months in least developed countries (e.g. Nigeria) and 38% of infants worldwide are exclusively breastfed.

-

Infants who are not breastfed are 15 times more likely to die from pneumonia and 11 times more likely to die from diarrhea.

-

Undernutrition is associated with 45% of child deaths.

-

At least 800,000 children's lives could be saved each year if they were optimally breastfed.

Working mothers in rural Africa have to either bring their children to work and breastfeed in public or leave their children starving at home while they are at work.

Severely malnourished child on the verge of death

Breast pumps for hospitals and employers are not applicable in low-resource settings due to limited accessibility to hospitals and nonexistense of workplace breastfeeding facilities.

Personal breast pumps on the market are not suitable for low-resource settings.

Key problems:

Manual pumps

-

Time consuming

-

Requires large amount of water to clean

-

Unable to pump sufficient amount of breast milk

Electric pumps

-

Expensive

-

Hard to maintain in limited clean water and power source settings

-

Difficult to use

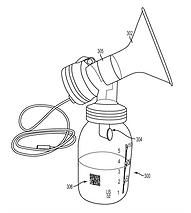

Purchased and studied the most popular manual breast pump on US market.

Interviewed a nursing mother who has been using an electric pump.

Insulating storage space for breast milk.

Bulky electric plug limits the place the pump can be used.

The pump is large, complicated, and noisy when in use.

Requires a nursing bra to secure the suction cup and bottle.

Ideation

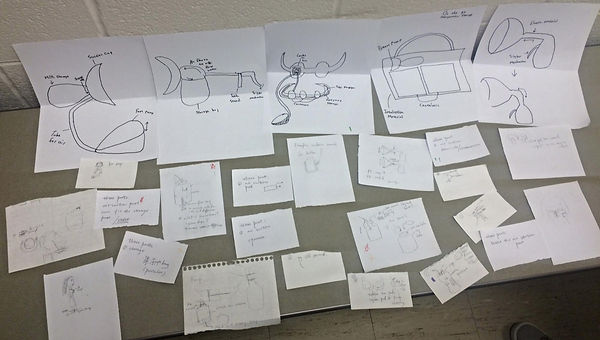

Developed empathy for mothers in low-resource settings through synthesis of research findings.

Identified user requirements to guide design ideation.

Brainstormed design ideas through divergence and convergence of ideas.

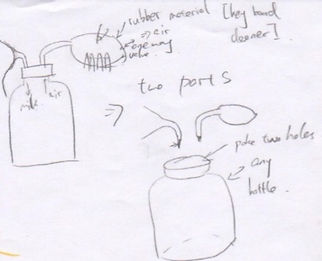

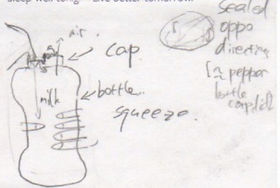

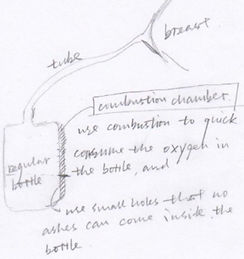

Created sketches of ideas for internal and external communcation.

Interviewed potential users, stakeholders, and experts with design ideas for feedback.

Utilized Decision Matrix Analysis to select the best design.

Created rapid prototypes to demonstrate and test design concepts.

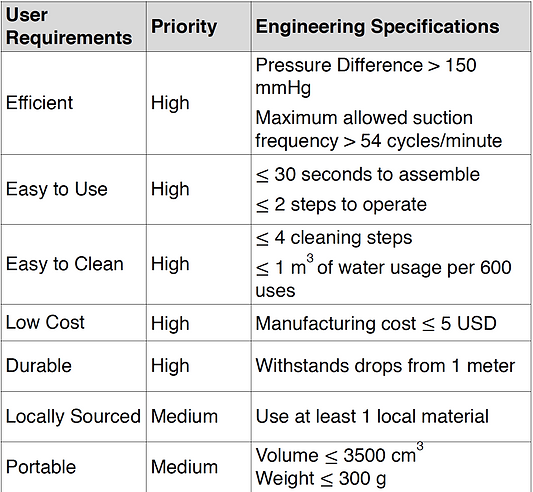

User requirements identified:

-

Easy to use

-

Easy to clean

-

Efficient

-

Low cost

-

Durable

-

Mechanically powered

-

"One size fits all"

High Priority

Medium Priority

Low Priority

-

Locally-sourced

-

Portable

-

Preserves milk

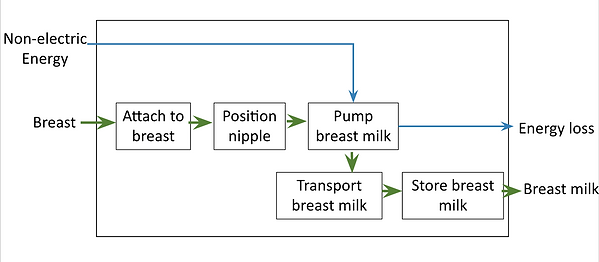

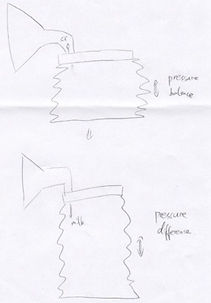

Functional Decomposition

Generated 29 concepts from team brainstorming.

User requirements & Engineering specifications generated from research synthesis:

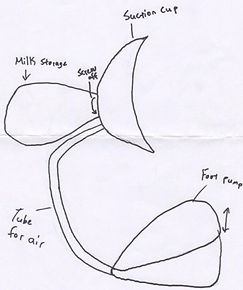

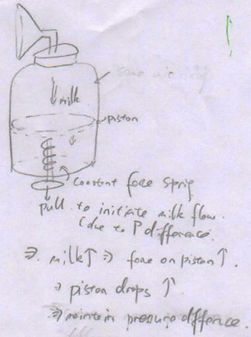

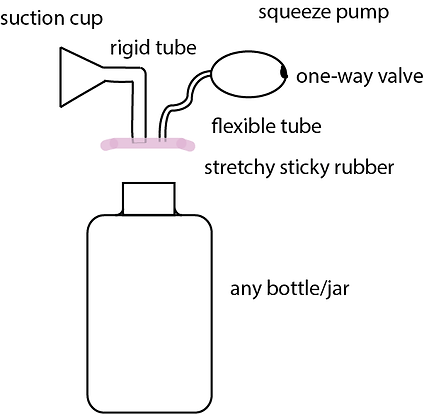

The chosen design is an integration of two concepts.

Rapid prototype of the chosen design.

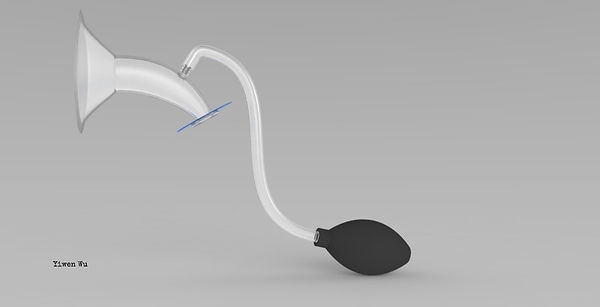

Preliminary CAD model

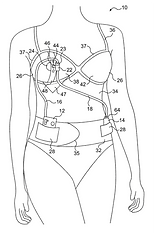

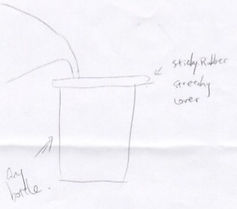

Stretchable silicon lid (shown in blue) allows the pump to be attached to a bottle of any lid size.

Soft tube is directly connected to the rigid tube to allow a smaller stretchable cover base for compatibility with small bottle lids (e.g. water bottle)

Sideview

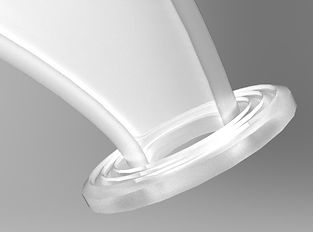

Plastic suction cup - Soft tube connector

Plastic suction cup - Stretchable silicon lid connector

Implementation

Implementation

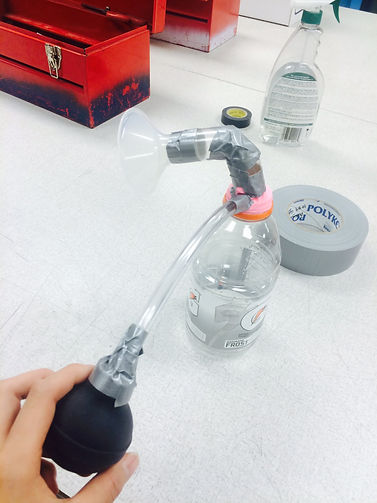

Constructed theoretical model and functional prototypes to evaluate, refine, and optimize the design through testing and engineering analysis

Refined the design through iterations of design, build, and test

Conducted qualitative and quantitative tests to evaluate design performance against required engineerings specifications

Documented and presented the design process and results through videos, photos, reports, and presentations

Squeeze pump

Medela pump

Suction mechanism testing

Comapred suction effects of a squeeze pump and Medela pump with control variables and a balloon simulating the breast.

Original state

Suction created by the pump

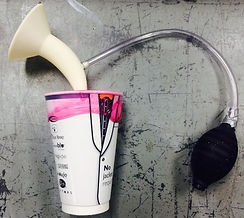

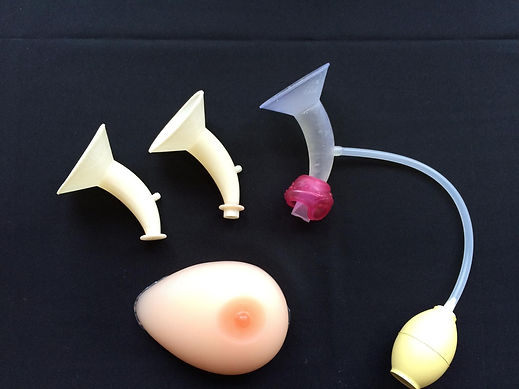

Functional prototype with 3D printed part

Design compatibility test

Coffee cup

Water bottle

Medela breast pump bottle

Prototype suction test

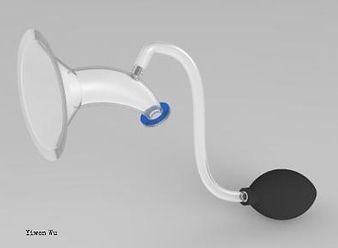

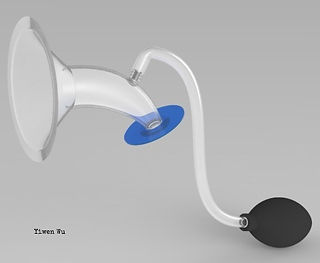

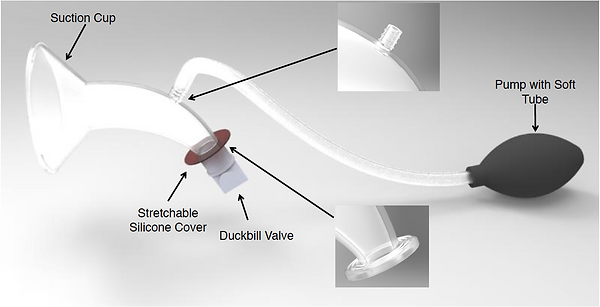

Final design CAD model

Suction cup: Made at a 60°angle to prevent milk from flowing inside the tube and to ensure that there is no bottle interference.

Pump with soft tube: Extrusion connecting the cup and the tube has ridges to ensure a tightly sealed connection.

Stretchable silicone cover: Securely attach the breast pump to any bottle.

Duckbill valve: Constrain the pressure volume to the cup, tube, and pump.

Iterations of prototypes with fake breast for testing

Qualitative comparison test with the same fake breast

Design prototype

Hand pump

Electric pump

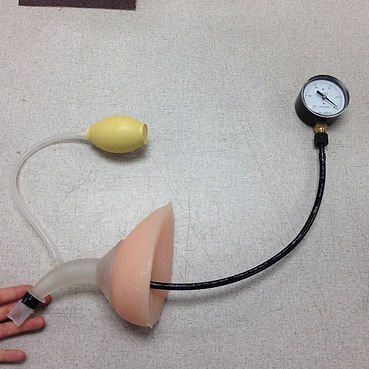

Quantitative pressure test setup

Quantitative test results

User requirements Test results

Efficient

Easy to Use

Easy to Clean

Low Cost

Durable

Locally Sourced

Portable

Max inner pressure difference: 178±6 mmHg

Pumping frequency: 72 ± 4 times per minute

Average assembly time: 27.8 ± 6.1 sec

Average disassembly time: 10.3 ± 3.1 sec

Cleaning steps: 4 steps

Water consumption: 0.65 m3 of water usage per 600 uses

Mass manufacturing cost: 1.23 USD

Withstands drops from 1 meter

Fit bottles of cap diameter from 1 in to 3.5 in

Weight: 116.9 g

Volume: 951 cm3

Design Expo Poster

Team Photo at Design Expo

Future Work

-

Decrease operation fatigue

-

Human testing

-

Collect breast milk flow rate data

-

Compare with other products

-

-

Lifetime validation

-

Milk preservation

-

Incorporate milk preservation technology

-